1. The structural form of the water pump has an impact on the size, structural form and internal layout of the pump room, so it has a great influence on the cost of the pump station. For example, when the water source level is very low and a very deep pumping station must be built, choosing a vertical pump can reduce the area of the pumping room and reduce the cost. For another example, there is a big difference in the layout of the suction and pressure water pipelines in the station between a single-suction vertical joint water pump and a double-suction horizontal joint water pump.

2. The normal water absorption conditions of the water pump should be ensured. Under the premise of ensuring that cavitation does not occur, the allowable vacuum height of the water pump should be fully utilized to reduce the burial depth of the pump station and reduce the project cost. At the same time, it is avoided that the installation height of each pump in the pump station is too different, resulting in uneven foundation burial depth of each pump or an increase in the burial depth of the entire pump station.

3. A water pump with higher efficiency should be selected. For example, try to use a large pump, because generally large pumps are more efficient than small pumps.

4. According to the different requirements of water supply objects for water supply reliability, a certain number of backup pumps are selected to meet the water requirements in case of accidents: when it is not allowed to reduce the water supply (such as the water supply of blast furnaces and open-hearth workshops of metallurgical plants) ), there should be two sets of backup units; when the water supply is allowed to be reduced in a short period of time, the backup pump only guarantees the supply of emergency water; when the water supply is allowed to be interrupted in a short period of time, only one backup pump can be installed. Pumping stations in urban water supply systems generally have only one backup pump. Usually the backup pump can be the same model as the largest working pump in the pumping station. If there is a sufficiently large highland pool or water tower in the water supply system, which can partially or completely replace the pumping station for short-term water supply, the pumping station does not need to be equipped with a pump, and only a set of spare units can be stored in the warehouse. The standby pump, like other working pumps, should be ready to start at any time.

5. When selecting pumps, try to combine regional conditions and give priority to products that are locally manufactured, produced in series, relatively stereotyped and have good performance.

]]>1. Water pump noise caused by improper installation

When installing, we pay attention to one level, two stability and three stability. Flat means horizontal. When installing the water pump, the feet must be kept level (special circumstances are a different matter) and cannot be tilted. Stable means it must be stable and cannot be loose and wobbly. Sturdy means that the installation foundation must be solid and stable, and one side cannot be grounded and the other side cannot be suspended in the air. In addition, in order to avoid resonance and noise, the pipe pump feet should be equipped with vibration isolation pads, and the inlet and outlet must be equipped with expansion joints (soft joints). Why do we do this? Since the motor of the water pump is inherently noisy and accompanied by slight vibration during operation, if no vibration isolation pad is installed, a chain reaction will occur between the water pump and the foundation, and the resonance will intensify the vibration. If expansion joints are not installed at the inlet and outlet, the vibration and noise of the motor will be transmitted to the pipeline, and the pipeline will act like a resonance chamber, which will further intensify the vibration and noise. At the same time, the pipeline will also emit sound and vibration under the action of water flow resistance and pressure in the pipeline, so expansion joints must be installed to eliminate resonance and resonance between the pipeline and the water pump.

2. Noise caused by unbalanced water pump impeller

Some water pumps have been used for a long time, and the impeller may be damaged by debris sucked into the pump cavity during operation, or other reasons may cause the impeller to lose balance, causing the impeller to lose its balance. The motor bearings have different load-bearing strengths, causing noise. At the same time, the motor shaft will also be affected by the unbalanced impeller, causing it to be out of center and causing noise.

3. Noise caused by bearing damage

Some customers install the water pump outdoors and use it without any cover. Rainwater will be sucked in by the fan blades from the motor windshield. If it invades the bearing chamber of the motor back cover, the bearing will be oxidized and rusted, and the bearing ball will no longer be smooth. , mechanical noise will be emitted. If it is installed indoors, this problem generally does not occur, but there will be another situation. If the mechanical seal is damaged and is not replaced in time, it is still used and the water is not cut off. The mechanical seal loses its sealing effect and the pump chamber is damaged during operation. The internal pressure causes the water in the pump body to spray out. The water retaining ring on the motor shaft can protect the motor bearings from water intrusion for a short period of time. However, if more and more water sprays out and invades the bearing chamber, it will also damage the bearings. At this time, the sound of the working water pump may be as loud as a train running over the rails.

2. When it is found that the mechanical noise of the motor increases and the temperature rise of the bearing is abnormal, the lubrication condition of the motor bearing should be checked. If the grease becomes discolored or dirty, it should be replaced in time.

3. When oil leakage is found in the sealing seat, you can loosen the screw plug on the sealing seat and run the oil pump. When oil comes out and smells like aviation oil, it can be determined that the mechanical seal has failed. Take the in-line pump out of service to quickly replace the mechanical seal.

4. How to replace failed mechanical seal:

(1) Prepare the workbench (ground) and disassembly and assembly tools for placing pump parts. Do not place them randomly to avoid damaging the pump parts.

(2) Make sure the motor is in maintenance status before disassembly; unscrew the oil filling screw plug; use a straw to suck out the lubricating oil in the seal seat cavity.

(3) Disassemble the split coupling: first unscrew the hexagon socket screws fixing the coupling, and then gently pull half of the coupling off the shaft slowly (be careful not to fall off). Use a torx wrench to unscrew the pump shaft lifting bolt and stopper, let the impeller slowly sink to the pump body, remove the other half of the coupling, and take off the pump shaft retaining ring.

(4) Remove the sealing seat: Unscrew the sealing seat compression nut, gently remove the sealing seat (note: do not break the rubber oil seal on the seat) and clean it.

(5) Disassemble and clean the bearing seat: first lightly move the bearing seat, then use the disassembly bolt to lift the bearing seat, and lift it down along the pump shaft to remove it. Use jet fuel to clean the bearing and seat, dry and dry before installation. Apply a little No. 20 mechanical oil for lubrication and protection.

(6) Disassemble the mechanical seal: Grasp the seal spring and lift it up along the pump shaft to disassemble it.

(7) Mechanical seal assembly: Apply a layer of clean No. 20 lubricating oil on the mirror surfaces of the dynamic and stationary rings: apply lubricating oil to the guide bearing seat, first gently position the static ring and install it into the guide bearing seat; then install it on the pump shaft Apply lubricating oil, and gently install the moving ring part of the mechanical seal onto the pump shaft. Push the sealing ring gently with your hand and it should be able to expand and contract freely (note that the anti-rotation surfaces of the moving and static ring parts are assembled in place).

(8) Install the sealing seat: First install the rubber oil seal on the sealing seat, then install the sealing seat into the pump cover and press it on the bearing seat, and tighten the nut.

(9) Install the coupling: first install a retaining ring on the motor shaft head, install a coupling, then install a stopper on the pump shaft end and the coupling groove and tighten the bolts with a torx wrench (lift the pump shaft 3 ~5 mm away to provide mechanical seal prestress): Install the other half of the coupling and tighten the hexagonal socket screws, which must be tightened. Correct inspection requirements for installing a coupling: the upper and lower clearance of the split coupling is even; turn the coupling several times by hand to check for flexible rotation.

(10) Perform a test run according to the key points of use to check whether the mechanical seal is replaced correctly and whether the pump unit is operating normally.

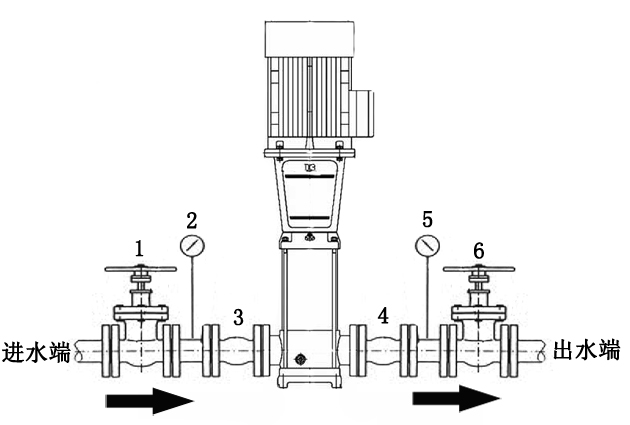

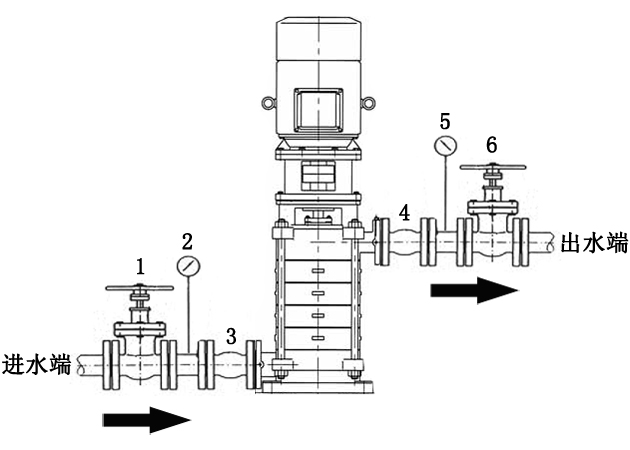

Definition: What we call a pipeline pump refers to a centrifugal pump whose inlet and outlet are on the same straight line, so the pipeline pump is also called a pipeline centrifugal pump. Pipeline pump is not a professional term in the pump industry. It is a private term based on the characteristics of the pump – when installed, it is installed on the pipeline just like a section of pipe, so it is named pipeline pump. Figures 1 and 2 below show typical vertical single-stage pipeline pumps and vertical multi-stage pipeline pumps.

? ?

? ?

As shown in Figure 1, it is a vertical single-stage pipeline pump, and Figure 2 is a vertical multi-stage pipeline pump, with the same inlet and outlet, which is very convenient to install. In particular, the vertical multi-stage pipeline centrifugal pump is now widely used in the water supply field. Typical products are CRF vertical multistage centrifugal pump

Features: Since pipeline pumps are centrifugal pumps, they naturally have the characteristics of centrifugal pumps, including not only simple structure, numerous models, wide range of performance, relatively low price, especially the feature that the inlet and outlet water are in the same straight line, which makes installation more convenient. , It is not necessary to disassemble pipes etc. during general maintenance.

Summary: Pipeline pumps are cheap, easy to install and do not need to dismantle pipelines during general maintenance. These three characteristics determine that pipeline pumps are widely used in pipeline pressurization in industrial and civil fields. Including not only the pressurization of industrial production water, the pressurization of various cooling circulating water, the pressurization of tap water pipes in various civil or commercial buildings, the pressurization of various central air-conditioning circulating water, etc.

It should be noted that there are subtle differences between pipeline pumps and pipeline booster pumps. Pipeline booster pumps are a general term, which means that any booster pump that can be used for pipeline boosting can be a pipeline booster pump. Pipeline pumps It is just a type of pipeline booster pump. Pipeline booster pumps may also include horizontal structures or vertical multi-stage centrifugal pumps with water inlet below and water out above. As shown in Figure 3, it is a typical vertical multi-stage centrifugal pump with bottom in and top out. It is also a pipeline booster pump, but it cannot be called a pipeline pump.

Figure 3, vertical multi-stage centrifugal pump, water inlet from the bottom and water out from the top

1. The structural form of the water pump has an impact on the size, structural form and internal layout of the pump room, so it has a great influence on the cost of the pump station. For example, when the water source level is very low and a very deep pumping station must be built, choosing a vertical pump can reduce the area of the pumping room and reduce the cost. For another example, there is a big difference in the layout of the suction and pressure water pipelines in the station between a single-suction vertical joint water pump and a double-suction horizontal joint water pump.

2. The normal water absorption conditions of the water pump should be ensured. Under the premise of ensuring that cavitation does not occur, the allowable vacuum height of the water pump should be fully utilized to reduce the burial depth of the pump station and reduce the project cost. At the same time, it is avoided that the installation height of each pump in the pump station is too different, resulting in uneven foundation burial depth of each pump or an increase in the burial depth of the entire pump station.

3. A water pump with higher efficiency should be selected. For example, try to use a large pump, because generally large pumps are more efficient than small pumps.

4. According to the different requirements of water supply objects for water supply reliability, a certain number of backup pumps are selected to meet the water requirements in case of accidents: when it is not allowed to reduce the water supply (such as the water supply of blast furnaces and open-hearth workshops of metallurgical plants) ), there should be two sets of backup units; when the water supply is allowed to be reduced in a short period of time, the backup pump only guarantees the supply of emergency water; when the water supply is allowed to be interrupted in a short period of time, only one backup pump can be installed. Pumping stations in urban water supply systems generally have only one backup pump. Usually the backup pump can be the same model as the largest working pump in the pumping station. If there is a sufficiently large highland pool or water tower in the water supply system, which can partially or completely replace the pumping station for short-term water supply, the pumping station does not need to be equipped with a pump, and only a set of spare units can be stored in the warehouse. The standby pump, like other working pumps, should be ready to start at any time.

5. When selecting pumps, try to combine regional conditions and give priority to products that are locally manufactured, produced in series, relatively stereotyped and have good performance.

]]>1. Generally, pipeline pumps are marked. The arrow on the pump body or base points to the water outlet of the pipeline pump, and the remaining one is the water inlet.

2. Observe the structure. The closer to the base is the water inlet. The right side of the picture below is closer to the base. This is the water inlet. The water flows in and is sucked in by the impeller (point 2) and then thrown out to the water outlet and enters the pipeline.

3. Generally, the water outlet of a pipeline pump has a copper exhaust valve, which is used to exhaust air or install other sensors. The outlet with this component is the water outlet. If you still can’t tell, please contact us for technical support.

]]>1. The recommended installation method for pipeline pumps is vertical installation, that is, the water inlet and outlet are parallel to the ground. In some places, if other restrictions require horizontal installation (the water inlet and outlet are vertical to the ground), the power should not exceed 4KW.

2. The base of the pump should be kept as level as possible to prevent the motor bearings and shaft seals from being easily damaged by unbalanced forces. Generally, in order to prevent the accumulation of air at the water inlet end, the water outlet end can be slightly lower than the water inlet end, which can effectively prevent air from accumulating in the pump chamber and causing a lack of pressure.

3. Whether the pump is used alone or in combination with the water pump control cabinet for automatic operation, it is recommended to install inlet and outlet gate valves for water in and out to facilitate maintenance and debugging.

4. If the water outlet has a higher height upward, it is recommended to install a one-way valve or a water hammer preventer at the water outlet.

5. It is recommended to install soft connections at the water inlet and outlet of the pump to facilitate installation and maintenance and to prevent vibration from being transmitted to the external pipe.

6. The inlet and outlet pipes of the pump should have independent supports, and the weight of the pipes cannot be added to the pump.

7. The water inlet pipe of the pump must be larger than or equal to the pipe at the water outlet of the water pump to prevent the water inlet from not being able to keep up with the pressure during water supply.

8. The water inlet of the pump should not be too long, especially when the water source is lower than the pump, the length and height must be paid attention to, otherwise it will not be able to absorb water or serious cavitation will occur.

9. The end of the water inlet pipe equipped with a bottom valve should be kept vertical. If it cannot be kept vertical, the valve will not close on its own, causing water leakage.

]]>In fact, this is a common problem of many cheap automatic booster pumps. The main reasons for this phenomenon may be as follows:

1. The check valve is leaking. The check valve itself can only go in but not out. If a check valve with poor quality is used, when the water pressure in the pump chamber increases, the pressurized water will seep back into the water inlet end of the pump, causing The pressure inside the pump chamber decreases. After the sensor detects the decrease in water pressure, it will restart the booster pump to compensate for the pressure. Since there is no water in the water outlet direction of the pump, the pressure is quickly replenished, and the booster pump immediately goes into sleep mode again. The reciprocating cycle causes this phenomenon of beeping and stopping. The solution is to replace the one-way check valve with a quality-approved one. In fact, most of the causes of beeping and stopping are caused by the check valve.

2. There is a leak in the pump outlet pipe. The principle of water leakage in the direction of the outlet pipe causing a beep and stop is the same as the leakage of the check valve. The reason is that the water pressure in the pump chamber is reduced and the water pump is restarted to compensate for the pressure. Since the water output in the outlet direction is very small , causing the pressure to rise to the set pressure value in a short period of time and causing the booster pump to shut down to maintain pressure. After the pressure is reached, the water pressure will drop due to water leakage, and the booster pump will replenish the pressure. The reciprocating cycle will cause a beeping and stopping phenomenon.

3. Sensor failure. This phenomenon will also occur when the pressure feedback is inaccurate. The principle is actually the same. When an incorrect low pressure is fed back, the booster pump will also compensate for the pressure and cycle back and forth.

4. The frequency of water use is too high. If the booster pump is controlled by pressure difference, it will also cause the phenomenon of starting and stopping when water is used frequently. The reason is the same as water leakage in the outlet pipe, and this situation may occur more frequently when it stops, especially if there is no pressure tank to stabilize the pressure. If you want to completely eliminate this situation, it is recommended to change the differential pressure controller to a frequency converter control, or directly replace it with a new variable frequency booster pump to solve the problem of beeping and stopping when using water.

]]>1. The water heater cannot be used normally. If the water pressure of the water heater is not enough to work properly, there is no need to pressurize the entire household water pipe network. It only needs to be partially pressurized in the cold water inlet pipe of the water heater to solve the problem. This kind of special booster pump for water heaters is small in size, has low power consumption, and is low in cost. Usually a 50-150 watt pump is enough, and the cost ranges from 200 to 400. Generally, the flow rate can meet the 9L/min of the shower head, and the pressure can be increased by approximately 1-1.3 kg, which can fully ensure the normal operation of the water heater.

2. The water pressure is low and the water flow is too small. Low water pressure and low water flow will also seriously affect daily life, such as washing vegetables too slowly and being unable to flush the toilet. This solution is more expensive than the solution introduced in item 1 above, because the flow rate of the booster pump is much larger, and noise issues must be considered. The water pump flow rate is generally at least 1-1.5 tons/hour, and the lift should be about 15 meters (that is, it can generate 1.5 kilograms of water pressure) to have a good experience. The power of the water pump motor with this parameter ranges from about 0.37-0.55 kilowatts. The water pump The water inlet and outlet interface is usually a 1-inch threaded opening, and a 1-inch opening needs to be added to change it to a 4-point opening (household water pipes are generally 4-point). If you don’t care about noise or water pressure stability, just buy a water flow pressure differential automatic booster pump that costs 300-500 yuan; if you mind noise and water pressure stability, then a variable frequency automatic booster pump that costs about 1,500 yuan. The pump is specially designed for you.

3. No water is available during peak periods. This situation is more expensive and complicated to solve because no water enters the network during peak periods, and even if you install a booster pump, it will be ineffective. Therefore, in this case, the booster pump must be installed outdoors on the first floor to ensure a continuous boosting effect. The water pump flow rate should also be 1-1.5 tons/hour, and the head should be 15-20 meters (that is, it can generate 1.5-2 kilograms of water pressure) to have a good experience. The power of the water pump motor of this parameter is about 0.55 kilowatts, and the water pump inlet and outlet The interface is usually a 1-inch wire opening, and a 1-inch opening needs to be added to change it to a 4-point opening (household water pipes are generally 4-point). It is not recommended to buy a cheap booster pump that costs 300-500 yuan for this kind of installation outdoors, because you have to consider the impact of noise on neighbors.

]]>1. When the pumped liquid level is lower than the upper end surface of the pump impeller or the pump shaft, the pump should be equipped with a check valve, and the outlet end should be connected to a tee for water diversion. When in use, the pump should be filled with water and the Tighten the screw plug. The pipeline connections should be tight, especially the water inlet pipeline should not leak, otherwise the pump lift will be reduced or water will not be pumped. Before water enters the pump chamber, do not rotate continuously for a long time to avoid damaging the mechanical seal.

2. The motor coil is equipped with a safety protector. When the pump fails or the water cannot be pumped, causing the motor temperature to rise above the specified value, the circuit can be automatically cut off. After the fault is eliminated, the motor temperature rise drops and the operation can be automatically resumed. The booster pump motor is a capacitor-operated motor, and the rotation direction has been adjusted when the pump leaves the factory. If you need to replace the capacitor or rewiring, please wire according to the arrow direction mark on the pump body. To ensure safe use, please use a three-core safety socket with a ground wire.

3. When water leakage is found in the pump, stop it immediately and check to prevent internal leakage. If water leaks from the connection part with the motor, replace the mechanical seal. Check if the power is on. Check whether the power supply voltage used is consistent with the working voltage of the pump. Open the pump cover, remove foreign matter in the pump, reinstall the pump cover, and tighten it to normal.

For the installation parts of the water pipe booster pump, everyone needs to know the specific installation method and the installation method, so as to ensure that the family can use water normally. The above is the relevant introduction about the methods of boosting water pipes without electricity and the installation methods of water pipe booster pumps. When installing the water pipe booster pump, you must understand the method of boosting.

]]>